Expansion joint metal are used piping system, pressure vessels, valve, etc. To absorb thermal expansion, vibration and to react at predetermined pressure and forces. They used joint carry numerous type of media, including steam, emission gases, water, acid, alkalis and hydrocarbon. Expansion joint metal are designed as per EJMA, the international design standard for manufacturing expnasion joint metal.

In judging the design of a bellows convulation, consideration has to be given to pressure an temperature requirement together with movement and flexibility, the optimum solution can provide for a convulation of the unreinforced type, single or multi-ply construction for low flexibility and large movement and root ring reinforced type for high pressures.

Metallic expansion joint in different configuration such as tied, hinged, gimbals both in single and universal configuration, with material stainless steel, inconel, etc. The bellows expansion joint is a thin walled flexible element that allows growth in piping system while containing the pressure and medium flowing through it, each bellows has a unique working pressure, spring rate, and cycle life that entirely depend on its geometry and material. The bellows has several convulation that allows movement in axial, lateral and angular direction.

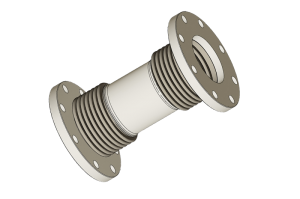

SINGLE EXPANSION JOINT (SEJ)

The simplest form expansion joint, of single bellows construction, designed to absorb all the movement of the section in which it is installed. The most common example is that of a single bellows designed to absorb axial movement only. This is often reffered to as an axial expansion joint.

The simplest form expansion joint, of single bellows construction, designed to absorb all the movement of the section in which it is installed. The most common example is that of a single bellows designed to absorb axial movement only. This is often reffered to as an axial expansion joint.

UNIVERSAL EXPANSION JOINT (UEJ)

Universal Expansion joint consist of two bellows separated by a short connecting tube and is capable of absorbing combination of axial, lateral and angular movement.

capable of absorbing combination of axial, lateral and angular movement.